Summary

| Date | 25.07.2018 |

| Duration | 1/2 day |

| Language | English |

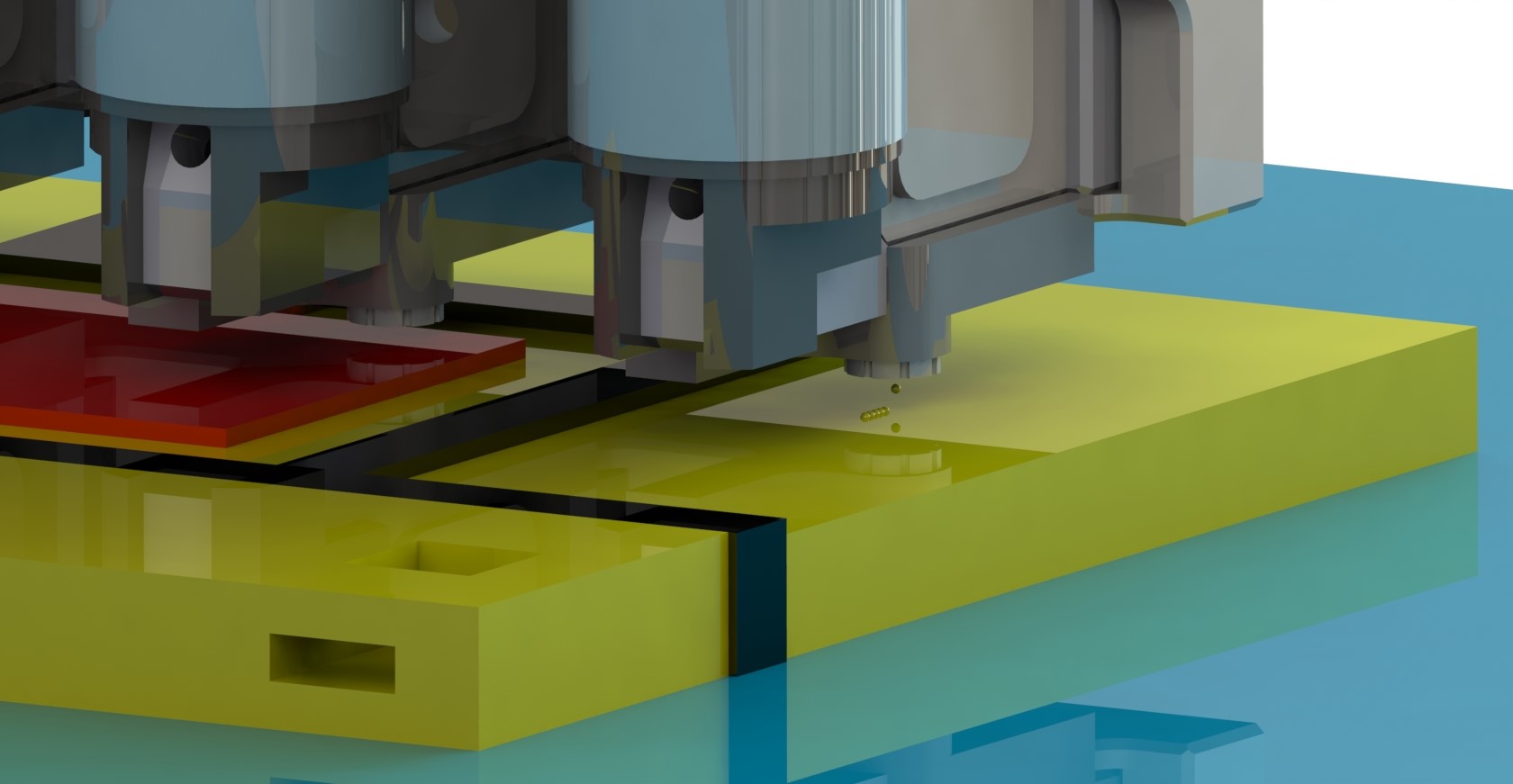

| Goal | Background lecture on ceramic materials, advanced ceramic-based additive manufacturing methods and hybridization, quality assurance measures, optimization by machine learning for obtaining high functional ceramic and multi-material components used in various fields, e.g. Mechanical engineering, Tool and mold making, Medical technology, Aerospace, Jewelry, Automotive industry, Chemicals and pharmaceuticals |

| Level | Beginner to Advanced |

| Prerequirements | Basic knowledge about conventional manufacturing methods, materials and additive manufacturing |

| Maximum number of participants | 80 |

| Location | Geoworks (by SLA), PSA Building, Level 7, 460 Alexandra Rd, Singapore (Visitors/Guests are required to register at self help kiosk with NRIC/workpermit/driving license/passport at PSA security at Level 1, Main lobby at south facing side of the building) |

| Registration Fees | none |